Beike & Xi'an Jiaotong University & Beihang: Aluminum-based composite materials with ultra-high ther

With the continuous development of the information industry and the continuous improvement of chip manufacturing technology, microelectronic devices are gradually miniaturized, integrated and high-power, and the heat dissipation problem has become a bottleneck restricting the further development of microelectronic devices. Due to the low thermal conductivity (< 300 W m-1 K-1), traditional electronic packaging materials can no longer meet the heat dissipation requirements of high-power electronic devices, and there is an urgent need to develop a new generation of electronic packaging materials with high thermal conductivity and low thermal expansion coefficient . In recent years, diamond particle-reinforced aluminum matrix (diamond/Al) composites have attracted extensive attention from researchers due to their high thermal conductivity, tunable thermal expansion coefficient, and low density. At present, the highest value of thermal conductivity of diamond/Al composites is only 770 W m-1 K-1, which fails to make full use of the high thermal conductivity of diamond. How to further improve the thermal conductivity of diamond/Al composites is an issue in the field Mainly solve the key problems.

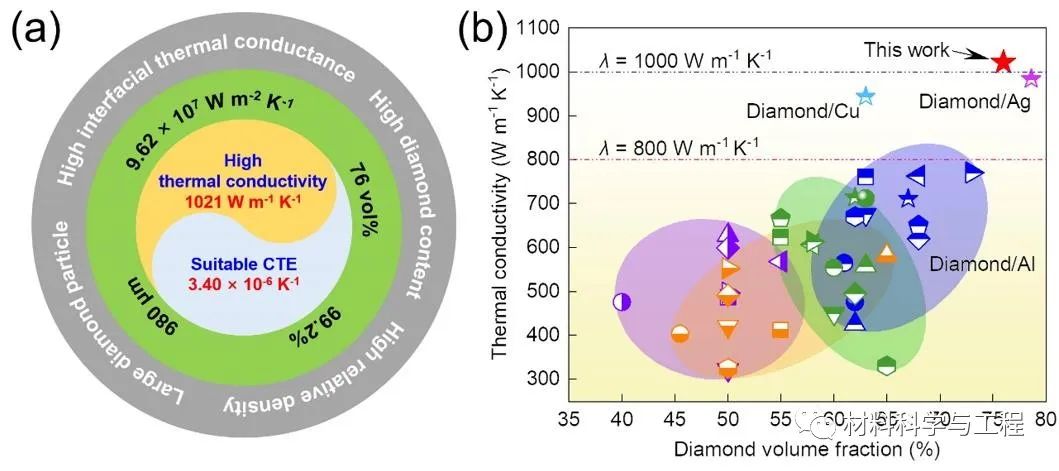

Recently, Professor Zhang Hailong of Beijing University of Science and Technology cooperated with Professor Wu Haijun of Xi'an Jiaotong University and Professor Zhao Lidong of Beijing University of Aeronautics and Astronautics to obtain thermal The diamond/Al composite material with a conductivity as high as 1021 ± 34 W m-1 K-1 (Figure 1) is the highest value of the thermal conductivity of diamond particle-reinforced metal matrix composites reported so far. The research results are titled Realizing ultrahigh thermal conductivity in bimodal-diamond/Al composites via interface engineering was published in Materials Today Physics (2022, 28, 100901).

Paper link: https://doi.org/10.1016/j.mtphys.2022.100901

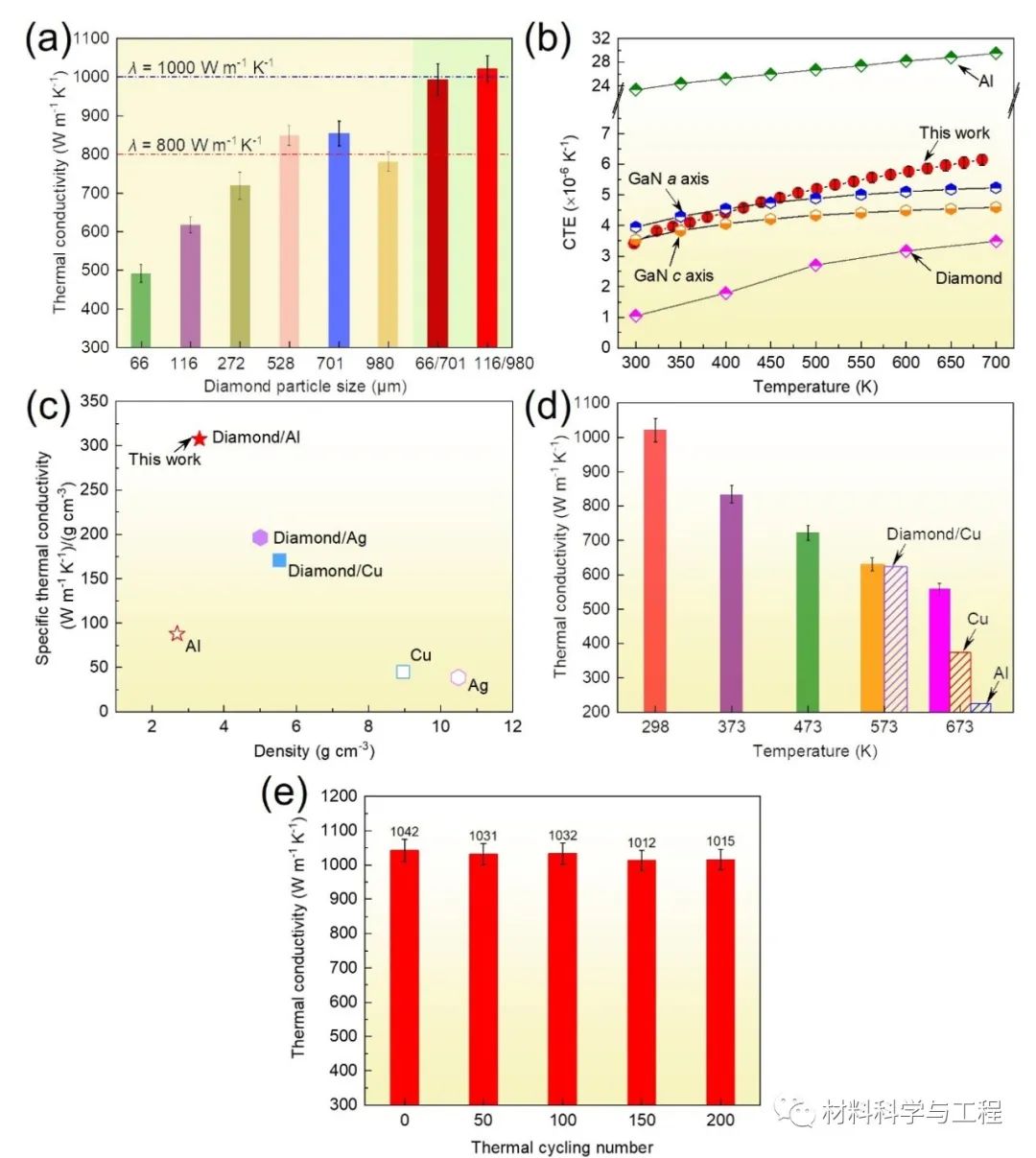

The research work uses double-diameter diamond particles to increase the diamond volume fraction and realize the densification of large-diameter diamond particles. By optimizing the discontinuous in-situ carbide interface layer to improve the interface thermal conductivity (Figure 2), using the synergy of multiple factors, Breakthrough in thermal conductivity of diamond/Al composites. The composite material also has a low thermal expansion coefficient (3.40 × 10-6 K-1) matched with semiconductor materials, high high-temperature thermal conductivity and stable thermal cycle performance (Figure 3), which can be used for high-power microelectronic devices. Effective heat dissipation is expected to replace existing electronic packaging materials and promote the development of electronic packaging technology.

Figure 1. (a) Strategies for achieving excellent thermophysical properties of Diamond/Al composites: simultaneous optimization of high interfacial thermal conductivity, large-diameter diamond particles, high diamond volume fraction, and high density; (b) thermal conductivity and Literature comparison.

Figure 2. The optimization scheme for Diamond/Al composites to achieve high interface thermal conductivity, large-diameter diamond particles, high diamond volume fraction and high density at the same time: (a) Double-diameter diamond particles increase diamond volume fraction and achieve large particle size Densification of diamond particles; (b) Discontinuous Al4C3 interfacial layer to achieve high interfacial thermal conductivity.

Figure 3. Thermophysical properties of Diamond/Al composites: (a) Thermal conductivity of composites prepared with diamond particles of different particle sizes; (b) Thermal expansion coefficient in the range of 298-673 K and semiconductor materials GaN, metal Al, diamond Comparison; (c) comparison of specific density thermal conductivity with diamond/Cu, diamond/Ag composite material, and high thermal conductivity metal; (d) comparison of high temperature thermal conductivity with diamond/Cu composite material, metal Cu and Al; (e) thermal conductivity Conductivity as a function of the number of thermal cycles in the temperature range 218-423 K.

*Thanks to the author's team for their great support for this article.

This article is from the WeChat public account "Materials Science and Engineering"